Keg… in summer… in the UK… it is a fucking pain in the backside. Currently I am having a “summer of fob”. (“Fobbing” is what happens when a beer is too foamy to serve, “foam on beer”, there are several ways fobbing can occur – carb level, temp, flow rate…)

Keg is quickly becoming core to my distribution business. In fact I’m slowly moving to less and less cask volume and considering dropping cask entirely so I can focus more on keg and packaged beers. But there’s a problem with keg – I’m getting higher ullage rates, and an ullage is effectively eliminated sales volume, work done for nothing – and that hurts my small business. It strains relationships with pubs and breweries too. I’m sat here as the middle-man copping the flack from either side.

There are key problems that I believe the UK beer industry MUST solve:

- Breweries should not be releasing beers that will gain over 1 vol of CO2 outside of the brewery. Let alone 2 or 3 vols! Surely? Is that reasonable? I’ve handled kegs that are up at 6 vol CO2 (in steel thankfully) and had a KeyKeg at 4 vol CO2 recently. That is on the verge of a KeyKeg’s maximum PSI rating at room temperature. If that 6 vol CO2 beer was in KeyKeg it could very well explode at cellar temperature. If breweries do this it’ll only be a matter of time before a serious injury occurs. That could be in the brewery, could be in distribution, could be in the pub…

- Distribution should be keeping kegs cool. This is unpasteurised unfiltered beer folks, it _will_ continue to attenuate somewhat. If you leave your kegs lying around for a week at 20C in summer they’ll probably gain some CO2 and thus result in fobbing. Causing issues at the pub, causing bad vibes, ullaged kegs, and hassles for both distribution and the brewery. I have a 10C coldstore and I’m not happy with that, but many “craft” distributors don’t have a coldstore at all. Hell, too many _breweries_ in the UK don’t. My own goal is to have a 4C-max coldstore for keg and packaged beer products. Some think me a fool… perhaps I am. It certainly isn’t currently a competitive advantage in a market where pubs will do anything to save a fiver.

- Pubs need to learn more about keg beer. The BII ABCQ is pretty much a waste of time, someone interested in their job & beer quality will already know _more_. We need a UK-tailored equivalent to Cicerone. Not just that – but pubs need to _not_ buy 2+ months worth of keg stock at once and then leave it in their 12C cellar. See above point: it _will_ attenuate further, the CO2 will increase, you _will_ have more issues with fobby beer. Ideally I’d love to see pubs with keg cellars below 6C… I’m dreamin’ now… Not every beer will have it in it to go far enough to cause problems, but some will. Just do not buy and store kegs for this long unless you can keep them cold. That’s just plain good practice regardless.

I don’t think a pub ought to have to worry about knowing how to vent kegs to reduce CO2 levels – but whilst the above 3 problems remain unsolved the best alternative I can think of is that pubs need to learn how to do this. Yet the current status in the UK is that most don’t even know how to manage within-acceptable-bounds cases with pressure and flow control. The highest level of UK cellar training is the BII ABCQ and, frankly, it is barely even what I would consider sufficient as a “new-joiner briefing” in a serious bar or pub. It’s crap, it’s designed for Wetherspoons and similar bar chains that have standardised products and support contracts.

I have _NEVER_ come across a keg I cannot get pouring. That 60 PSI steel keg I mentioned worked just fine after some venting, and the beer was actually pretty awesome. KeyKegs are even easier to vent.

Now… how do we fix this? <troll>Pasteurise all the keg beer?</troll>

</braindump>

(I have views on the lack of refrigeration in UK beer retail too… that’s one for another time though.)

Why don’t kegs have a pressure relief valve built in?

Probably cost. Especially on the plastic throw-away ones.

They probably should. I’m pretty sure some in the US do.

Part of learning to be a cellarman for cask is learning about venting and tapping the beer, the same must be done for keg. But too many places assume craft keg (by which I mean unfiltered/unpasteurized) can be treated the same as mass-produced keg.

Education and training need to be brought in. Even a single page handy guide would help start the process.

I’m still not certain what I think reasonable expectations are. Is venting CO2 from keg something we ought to expect pubs to have to do?

If breweries don’t get it too wrong and distribution & pub store cold (or store only briefly) then the problem should go away?

I wonder if it is at all common in the US?

Maybe “live” keg needs a new approach, a sticker: SERVE NOW, OR FOREVER HOLD YOUR PEACE

Maybe: BEST SERVED BEFORE 15/8/2015 – AFTER THIS TIME KEG MAY REQUIRE VENTING

And refuse ullages due to carb level. Make the pubs learn. As I’ve said above, I think carb level in keg is fixable 100% of the time – and that is my own experience of it. (It’s a bit of basic beer tech and physics really…)

So – how do you vent a keg/keykeg down to an acceptable level?

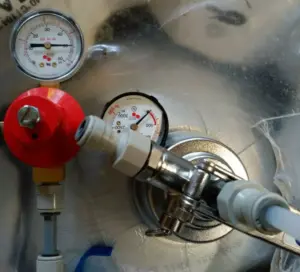

I’m planning something on this topic. You can vent both types of kegs via the coupler, releasing CO2 just as you do when you vent a cask.

It’s a little trickier than just bashing in a peg alas. So I’ve shot a bit of video footage, but I’m not happy with it and need to try that again. I also need to do a post with suitable pressure charts, etc.

Dave from Hardknott brewery has a video on venting KeyKeg here: http://hardknott.blogspot.co.uk/2012/08/keykeg-dispense.html

I thought of this post this evening as I watched a barman effortlessly filling an oversized half-pint stem glass with foam. Poor guy, it took him a good three goes to get a glass of beer out of the tap – the wastage rate on that beer must be horrific. (And it was that beer – I had a half from another keg tap which poured as calm as you like.) It does sound as if ‘live’ beer in a keg needs to be handled pretty similarly to ‘live’ beer in a cask, i.e. with care. The yeast is not mocked!

Pingback: Keg Beer Pressure in the UK | ALE.is.GooD

Pingback: Pressure Gauges – A Chat with Atlantic | ALE.is.GooD

Comments are closed.