Why? Why would I buy 10 kilometres of beer line? Specifically 5km of 5/16 and 5km of 3/8 beer line? That’s one big old pallet of beer line!

Well … it’s simply because 5km is the minimum order size. Simple?

But why not buy smaller amounts from an intermediary?

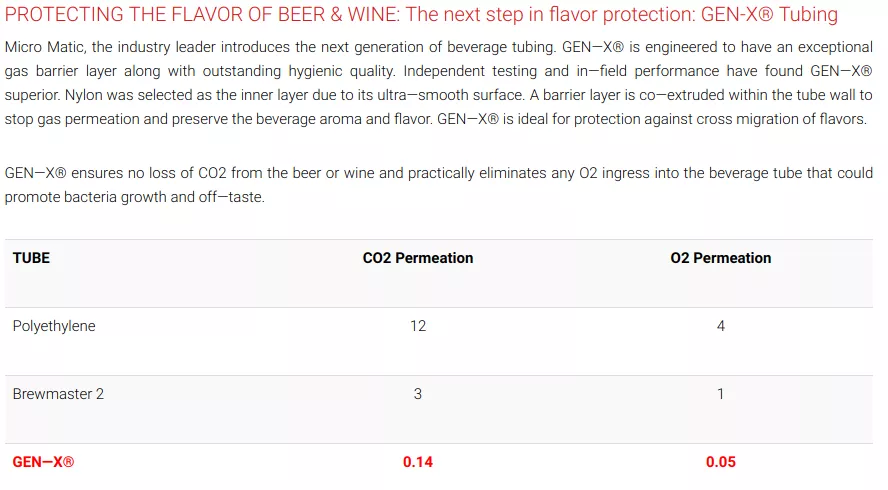

Because in the UK nobody stocks anything better than bog standard polyethylene beer line, aka “MDP” – “Low cost beer and soft drinks dispense tubing” … low cost, “low cost” could be considered the core theme of beer dispense in the UK. Generally “low”… low cost, low quality, lowest common denominator. (Don’t even get me started on the fact that many cask line installs are still using bloody PVC…)

It’s a bit of joke really… (of the depressing variety) pretty much the entire “indy”/microbrewery bar & pub beer scene in the UK is stuck with MDP. The “off the shelf” python and 3/8 tube is all this stuff, and none of the usual suspects for sourcing gear stock better. (You may be able to arrange for better I guess, but nobody does… beer line is just beer line, python is just python, right?)

The punchline to the joke is that big brewers like Heineken know how important consistency of quality is to their sales and accordingly they use Brewmaster II line in their installs.

There you have it… that pint of Heineken in the local probably comes out of a higher spec of dispense system than your pint of Cloudwater at UberTrendy Craft-n-Stuff bar.

Now… I’m personally not one for settling for the status quo. One should always strive to do better, achieve more… improve. So one of many things that came out of my research of craft beer dispense in the US was: hmmm, they have this special fancy barrier tube type beer line, what is it we us in the UK? *research*research* … oh, oh my, that’s a bit sad…

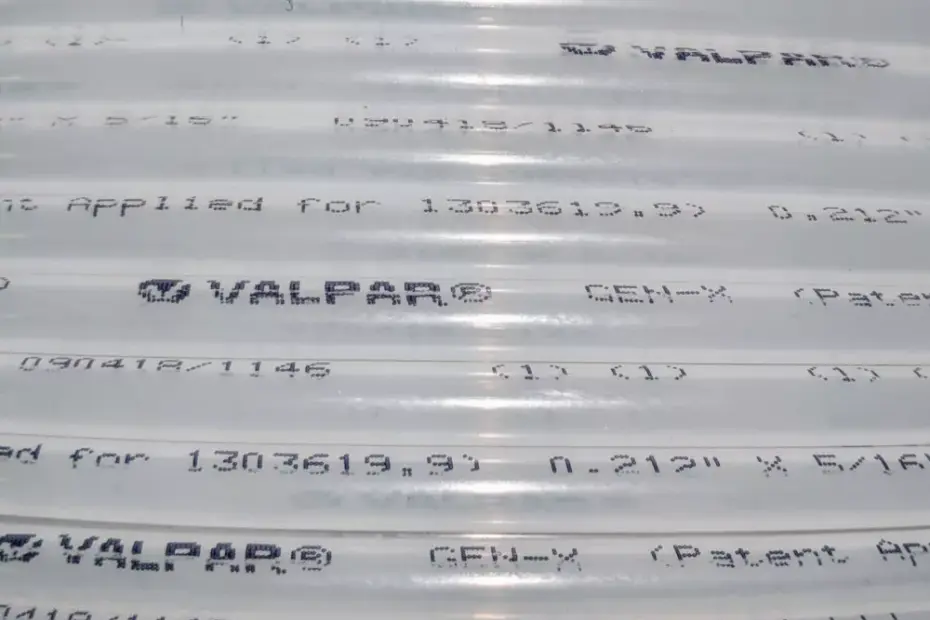

So I got in touch with Valpar over in Ireland… Valpar, owned by Micromatic, makes most of the beer line I see in the UK and it turned out they make some pretty good stuff. They key products being Brewmaster II (used by Heineken in the UK) and Gen-X (apparently used by Diageo for Guinness). Where I can buy the good stuff? Nobody in the UK stocks it. Oh… can I buy it from you direct? Yeesssss… if you want 5000 metres.

Think about it: there’s a company just over the Irish Sea that manufactures really good beer line that is shipped to countries all over the world and yet in the UK I cannot buy the stuff. My FOB detectors also come from Ireland. I get taps from the US and Italy. I even import gas regulators for top-end jobs… why is the UK so pants when it comes to quality beer equipment?

[Edit: Hey, so the fab folk over at The Malt Miller stock Brewmaster II – which is waaaaay better than MDP (see table below). So a worthy choice for a dispense install. Order from them here.]

This stuff isn’t madly priced per-metre but given I wanted both 5/16 and 3/8 the cost really adds up over 10km… normal MDP is about 10p per meter, the Gen-X is closer to 40p. So I had to wait about a year before it was possible to take about £4000 ex-VAT out of the business cashflow to invest in a big pallet of beer pipe. The price difference between Gen-X and Brewmaster II was low enough to make Gen-X seem a no-brainer, given the numbers significantly in favour of Gen-X: “The microbial growth tests indicate that the hygienic performance can be 2-3 times at least more effective than current market solutions.”

A few months ago it showed up and I was a happy dispense guy. Now if I do install work for you, you get Gen-X tube.*

So far we’ve had little chance to really get a feel for how much better Gen-X is than MDP. My couple of data-points so far are:

No more “line stench”? I do a fair bit of mobile bar stuff, and it is generally always the case after just one event that MDP line pumps out an “old beery” smell when you pump air through them at the next event. You can taste it even when you suck through even a short length. I’ve never been happy with this but have never been able to clean out that aroma. The Gen-X? So far this seems to be a thing of the past… after 3 events the keg tails I have used still don’t reek. (That said we are still re-doing all the pipework every 2 or 3 events.)

Sticky flavour beer taint a thing of the past? This seems to be the case. I put 3 kegs of a 10% hazelnut flavoured “pastry beer” type creature through a line… this was in there for 3 days and I then flushed with about 2 litres of water. No flavour or aroma of hazelnut (or anything) in the end of that water. I was pretty surprised by this, having in the past immediately had to (or wanted to) rip out and throw away the line after such a beer even after trying to line-clean TF outta it.

I would still advocate regular changing of beer lines though, even fancy plastic isn’t magic. Only time will tell what the real “craft beer” (unfiltered flavourful tastymank™) shelf-life of Gen-X is.

Technology… it works. Huh, whoda thunk it.

The reason I wrote this today (well, 2 months ago) was I saw a thing on the Twitters. Beer seemingly oxidised after 2 days sat in a line. It got me thinking about gas permeability of beer line… a generally known problem that is mitigated by fast throughput on kegs and weekly line cleaning. “Plastic isn’t magic” is a phrase I use a lot – O2 can get in, the higher the permeability the more likely biofilms will develop is one factor. Also, beer sat in a line will lose CO2 and oxidise. I don’t actually know how fast this will happen in a sense of yielding tangible/tastable flaws, but according to Valpar Micromatic numbers MDP is 80x more O2 permeable than Gen-X. I’m not yet convinced beer line O2 permeability is to blame in the case of the linked tweet… but I definitely have an idea for an experiment I want to run… <watch-this-space>, as they say.

* We’re still using MDP for most gas line and waste/outflow lines.