[This post originally written 2015-08-23 … has been refreshed 2018-09-16. Content has been edited without notes sometimes, other times comments have been inserted in [square brackets] or using this grey text colour where I think the historic content counterpoint adds value. Audience note: Jolly Good Beer is a “craft beer” business and as such this content is written for what you could call “craft beer bars” – the concepts are universal, but if any uncertainly exists you should consult with your supplier/brewer/dispense-technician before fiddling with your dispense system. (“Craft” note: we think all types of beer can be “craft” but don’t claim to be able to firmly define “craft” – we mainly use this term to identify a market segment, not a product type.)]

[[A “cleaned up” version of this was published by The Brewers Journal in October 2018.]]

I am heard to say, with increasing frequency [and still regularly]:

The UK is a decade behind the US in keg beer dispense.

Yesterday an American friend of mine responded to this with a scoffing “… at least.” Maybe I should start saying it is decades.

This comes to the fore more and more often lately as I deal with customers who’ve had “craft keg” installs that are, frankly, not fit for purpose. There are multiple factors to this and multiple “WTFs” I’ve seen in installs. But this post will focus on keg pressure.

[I am not a “qualified” cellar-build person. I’ve pondered doing the course but I gather it is basically just a how-to-plug-the-bits-together, that’ll be £1000 please, here-have-a-certificate. Update 2018-09-16] I am a “qualified” cellar technician as much as any such thing exists in the UK – having done the NCCSIM, but prior to that this article was written on the basis of a hell of a lot of research & reading, building bars, getting many varied keg beers pouring, and – probably most important – a sufficient background in physics. (I’m not talking physics major or anything, but I studied some physics through to university level and gas behaviours, flow, dissolvability, etc, are all fundamentals.) I’ve spoken to qualified cellar installers and, so far, not met one who knows anything about vols of dissolved CO₂ in beer [I have since met some who do understand this stuff… they are out there]. I guess you don’t need it if you’re always setting up to serve unchanging Foster’s et al in a 12°C cellar to standard parameters. (Cellar/keg temperature is another issue… deserving of a large post of its own.)

Everything changes drastically when it comes to “craft beer”. It’s not all just pasteurised lager with a “standard” 2.2 vol CO₂ [What is a “vol CO₂”? (PDF)] – suitable for a one-size-fits-all sort of configuration. It is *part* of the definition of some beer styles that they are at certain carbonation levels, and your top-pressure should be set accordingly. And then there’s KeyKegs, another ballpark – another game – entirely. If you have just one “craft” line for keg you’ll probably find yourself switching between KeyKegs and top-pressure kegs. (One reason many UK craft brewers are keen on KeyKegs is that it is less likely that crap cellar installs will cause their beer to be served under- or over-carbonated, KeyKeg basically eliminates one piece of fine-tuning at the pub end of things so it easier to support as well as eliminating an often overlooked infection vector from the beer. [Three years later and KeyKegs are becoming less popular due to increased costs and worries about their environmental credentials.])

What this boils down to is: every beer line should have a dedicated secondary regulator, and every secondary regulator should have a pressure gauge on it. (And the primary should have an out-side gauge allowing a safe maximum line pressure to be set (<50 PSI, <45 for Pet*cough*crap*cough*ainers) – albeit this can be set once at install and the gauge not needed. But the gauges aren’t an expensive upgrade and it is a useful bit of info when debugging cellar issues if you don’t have a pressure checking gauge handy.) Gauges should be checked for accuracy at install and about once per year. (Officially I think this is every 5 years, my experience now is many gauges in use are pretty fragile.)There is an alternative to this and that is to have a calibrated reference gauge (usually glycerine filled and with a rubber protective casing) that can be used to verify the pressure on a line, it is a bit less convenient than simply having trusted gauges on the dispense system though.

To add some credibility I’ll point you somewhere else at this juncture, go have a look at what Magic Rock, one of the UK’s top modern breweries, have to say about KeyKeg dispense: KeyKegs, differences & dispense issues…

But – what happens when you want to follow Magic Rock’s advice and have no gauges? You’re buggered is what. I’d not touch the thing, as you have no idea what the pressures are you could well take it past the safe limit.

But say you do take the risk and nudge it up a bit. That keg runs out. You want to put a normally carbed top-pressure keg on, you switch couplers, connect up. Over the next 2 days that beer gets increasingly carbonated and the last third basically pours foam. Bugger.

WITHOUT GAUGES YOU PROBABLY SHOULD NOT TOUCH REGULATORS.

(Or buy yourself a reference gauge.)

[All regulation-compliant UK dispense systems should be limited to 45 PSI for CO2 and 60/40 so it shouldn’t be possible to go higher, but I have also seen systems without these limits and “nitro” gas systems can go higher.]

Folk in the US with these “Flux Capacitor” setups aren’t spending all their money for shits and giggles. The kit on display is normally in the cellar/coldroom – putting it on display is a bit of marketing really – but the reasoning behind it is to highlight that these things are actually important & the bar takes it seriously. Albeit it does concern me a little, pressures should not need fiddling with – pressure should be set suitably for beer being plugged into the line and then that stays the same until you’re done. I think that functionally the kit is better off in the coldroom. But hey, it makes a good talking-point. This inspired me to put regulators on the front of my own mobile bar. (Although there are other good practical reasons for that, the front of the bar is easy to get to compared to the back through a stack of kegs and tangle of lines.) [I have since implemented a flux-capacitor-like system which is much less pretty and more utilitarian for Cloudwater’s dispense system in Manchester and soon also London.]

In this calendar year I’ve come across 5, *FIVE*, new keg installs that had no pressure gauges on the regulators. THREE of these were done after I told the folk getting the installs to ensure they had pressure gauges on their regulators. In the most recent case I was multiply-insistent. But on the day these professionals were adamant this was not needed… and in the end: no gauges. One of the 1st kegs put on the system was a KeyKeg, which was triggering the fob detector, and needed the pressure increased. Yet these professionals told the customer that my advice to them was wrong, that I didn’t know what I was talking about. (Oh, and this setup has kegs at ambient temp… *grumble* … but this means even more need for pressure adjustments! More chance of fobbing.) [This was in 2015 – things have improved a tiny bit since thanks to the “craft beer” sector slowly being schooled in how to do dispense, but it’s still pretty bad out there.]

So… in an attempt to basically explain that [some of the] the professionals don’t have a sodding clue: here are some guidelines for the different kegs out there…

KEYKEG (and other bag-in-container type pressurised kegs)

The great thing about KeyKeg is you cannot screw up the carbonation of the beer with top-pressure. Hell, you can use compressed air and save on the cost of food grade CO₂. (It’s up to the brewery to screw up carbonation, it does happen, too often… usually to the over-carbonated side… in which case KeyKegs can be vented.)

I can offer no better advice on KeyKeg to what Magic Rock have published. So pop along to their website to get the low-down on this topic.

The only addition I would make is that at UK cellar temperature (10-12C) I tend to run KeyKeg at 35 PSI by default, and this works in almost all cases. If needed I will increase pressure up to 45 PSI. If you need more than 45 PSI then your beer is either over-carbonated or the keg is too warm.

TOP PRESSURE KEGS

This is where the real problem with some of these keg installs lies.

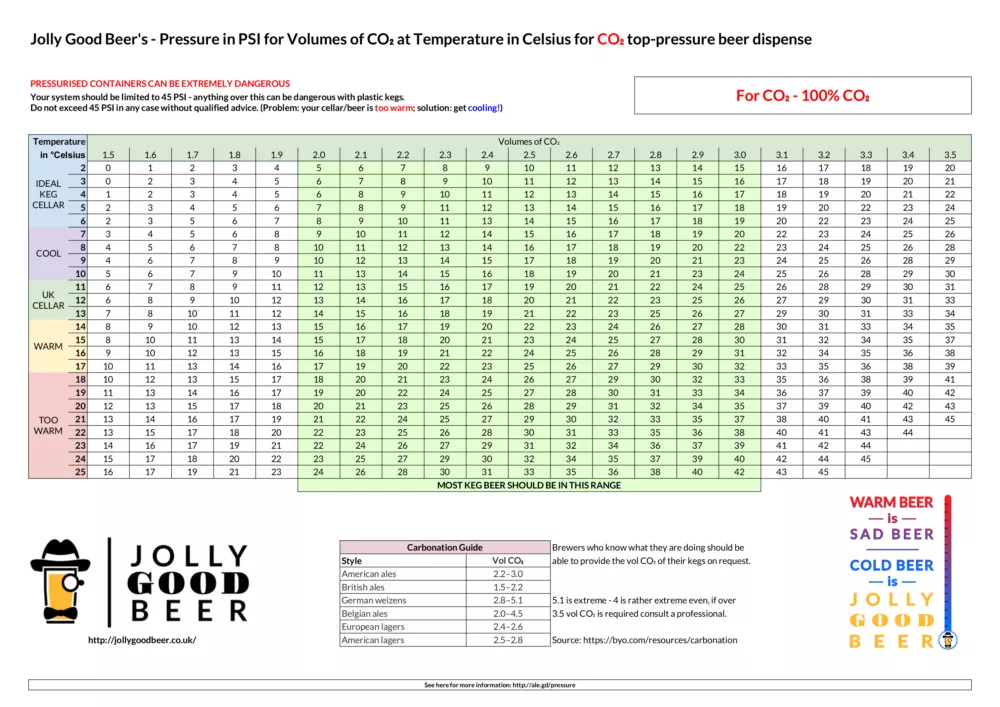

In light of hitting issues so frequently I have derived my own CO₂ pressure chart. As you do. De-rusting some of the old physics in my head in the process… the key differences between this and most other charts I can find are a) it is in Celsius and b) goes above 10°C… given UK cellars are often at 12°C this is somewhat essential. (Oh, and ambient temperature kegs at events, ah good old craft beer events, they’re another ballgame entirely.)

The 12°C cellar makes us in the UK a bit of an outlier really, here’s guidelines for cellaring Schneider Weisse: Draught Beer Guide – note that their pressure chart maxes out at 7.5°C… well, if you want to set the correct pressure for Schneider Weisse in a UK cellar look up 12°C against 3.5 vol CO₂ here:

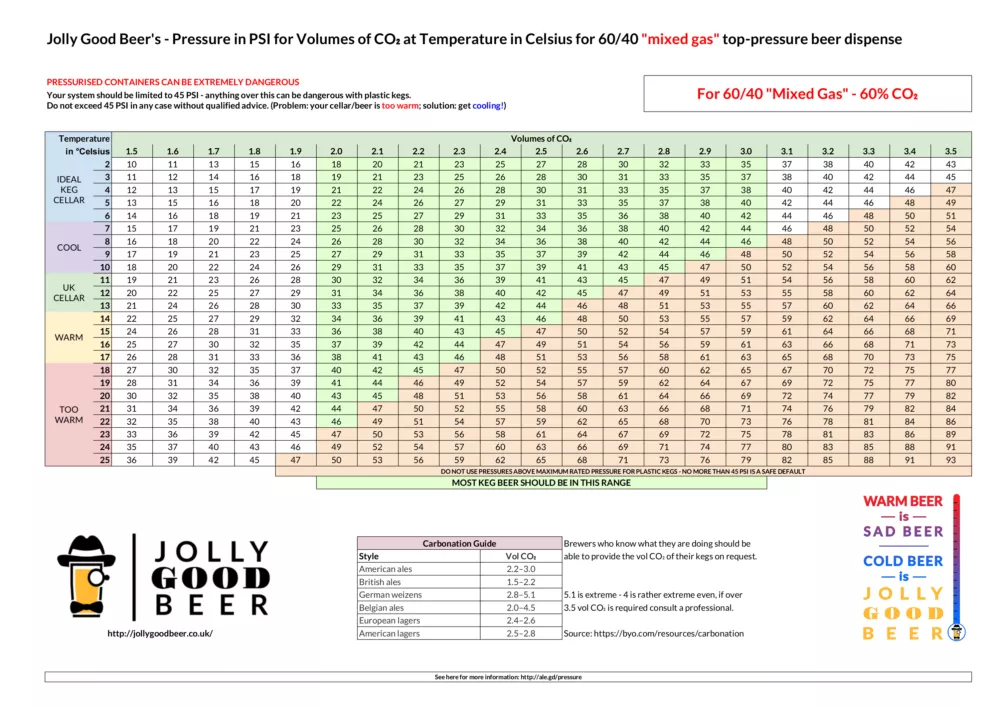

But wait, there’s more! There is stuff all information online regarding mixed gas. The prevalent use of 60/40 mixed gas in the UK is what I call “the great beer flattener” – systems seem often configured just to provide dispense pressure with no mind to carbonation level. You need quite high a pressure to get 60/40 dispense working perfectly for well carbed beers in a 12°C cellar. If you’re using plastic kegs then I would highly recommend against 60/40 gas as most kegs are rated to about 50 PSI and I personally limit them to 45 PSI. Pressurised plastic beer containers have caused injury. This chart was a bugger to derive, all I could find online was an Draught Beer Quality guideline update that is worked out for a maximum temperature of 4.4°C… in the UK? Hah! So I had to get my head around partial pressures to adjust the pressure formula, to give us:

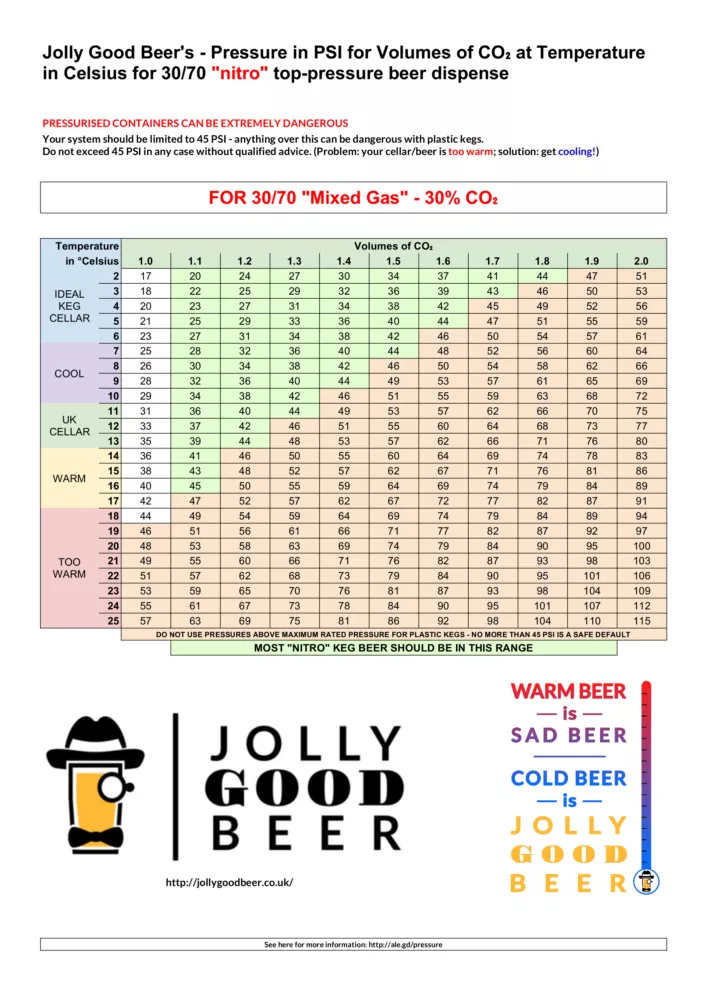

But wait, there’s more… how about some “thirty-seventy” “nitro” action too?

It should be kept in mind that if you smash through kegs in 2 days then carbonation isn’t going to change much and pressure is a lot less of a matter. You could even get by with plain N2 if you’re draining kegs fast enough (NOT RECOMMENDED!) and I’ve heard of some setups using compressed air like at GBBF (REALLY NOT RECOMMENDED!!). However it is my observation that in your typical multi-tap bar kegs can linger on a line for a week or so. This is not ideal… but it makes using correct top-pressure an essential part of the beer quality formula. [Ideally you should be turning over kegs in a maximum of 5 days.]

In the US there is this thing called “Certified Cicerone“, it is sort of an industry qualification. And it isn’t trivial like the UK’s barely-fit-for-purpose BIIAB ABCQ. I’m planning on doing the Cicerone exam when the opportunity arises and understanding pressures is a part of the syllabus [PDF]. (I’m a “Certified Beer Server… but that’s just an online multiple-choice test.) In fact in my opinion one of the best things BrewDog is doing for keg beer in the UK is putting many of their staff through Cicerone training and qualification. (Some of these staff are leaving BrewDog and spreading through the industry – taking their knowledge with them, this is great for everyone.)

The DraughtQuality.org website – a resource created by the US Brewers Association – is also a mine of technical information. (And key to the Cicerone syllabus.) This PDF for example is a much better overview of carbonation than my own ramblings: Understanding Dispense Gas [PDF]

Have I presented enough evidence to make it clear why being able to set the pressure level of your gas is essential if you want to serve different & varied keg beers through a beer line?

If not… what do you think. Why not?

Jolly Good Beer – putting the science in dispense!

Or maybe: Jolly Good Beer – putting the SENSE in dispense! 😉

#1: Do not exceed rated keg pressures…

Plastic keg remnants, HumanFish brewery, Slovenia. The rest was imbedded in the wall. pic.twitter.com/iVPDamtBZi

— Dominic Driscoll (@ThornbridgeDom) August 1, 2015

Some useful external resources from the Brewers Association:

Another very good post Yvan, let’s hope it leads to improvements all around for the benefit of all. Especially the safety advice on max pressures with non metal kegs !

Cheers, Steve

It amazes me that servers that have so much passion for beer can have little to no understanding of the cellar and gas workings. Hell I spent so much time down there cooling off with a hangover I got a good grounding before I started

Heya, great post. Would love some advice on venting overcarbed steel kegs? Also, does draw length not play into your recommended PSI calculator at all?

VENTING: If I ever get the time I’ll do some stuff re venting kegs. It needs a video really. The difference between KeyKeg and top-pressure kegs is the former is vented via the beer-out side of the coupler and the latter via the gas-in side.

To vent via the gas-in side you need to take out the no-return “duck bill” valve from the connector. (Unscrew the pushfit fitting, take out the rubber bit, screw pushfit back on.)

Then I attach a couple of feet of line with a flow restrictor on the end, fully restricted, then attach coupler. Use flow restrictor to carefully let off all CO2 pressure from headspace.

I tend to also have a pressure gauge as part of this, so I can let off CO2 in steps until a desirable pressure to achieved. Letting the keg return to equalibrium after each venging. It doesn’t take a lot of hands-on time,but the process can take a few days if you’re being careful. You can get away with being less careful as with top-pressure keg you can re-carbonate at least.

[Keep a coupler set up like this in your toolset as a “venting coupler”.]

All very helpful, thank you. I’ve used a system with flojets which had easily accessible flow controls, but with 100% CO2, now am on 60/40 without flojets and the flow controls haven’t been well-placed, so have become aware of some of the advantages and disadvantages of each aspect.

I’d personally build a system for straight CO2, flowjets if needed (using compressed air), and a flow-control close to or on the tap. Would have a compressed air supply for both flojets and keykegs. I’ve recently bought a load of US Perlick taps with FC on the tap, looking forward to using them… they are recommended by Stu at Magic Rock so are almost certainly “the shit”…

One customer of mine recently had a “craft beer” install with no gauges and to add insult to injury the flow controllers are hidden behind a wall that isn’t trivial to remove to access them. Customer knew no better of course and used the “professionals”…. ho hum.

Draw Length: Line resistance from line length and height delta impacts flow – and in US texts is used as a form of flow control. (Coil 8′ of 3/16 line in keggerator, etc)

What your line resistance tells you is that you may need more pressure to get the beer flowing out the tap. But you cannot simply bump up CO2 pressure… if you need more pressure you need to go to mixed gas so you can get the pressure up but not change the carbonation.

However commonly in the UK two things are used to make this different to what you’ll find in US texts. First FloJet pumps are used on beer lines to get around needing to use pressure to overcome line resistance. (So you don’t need to add pressure to “push” beer.) Second we use flow restrictors on everything generally. (So you don’t need to add line-length to slow-down beer.)

Pingback: Pressure Gauges – A Chat with Atlantic | ALE.is.GooD

Yvan,

Just saw this when searching for a carbonation chart. Thanks for putting it together…

The biggest thing to get right, which you explain, is to get the correct head pressure set for the temperature of the beer in the cellar and the brewery’s target Volumes. Then and only then should you worry about balancing that with line resistance.

If you pressure is 17psi on the keg that needs balancing with 17psi worth of resistance. You can cheat with flow controls, but I find them the source of many callouts and try to rely on the line resistance. The standard lines that we use here from Valpar have the following resistances:

Valpar 3/8 OD x .265″ MDP Tube = .13 psi/foot (.43 psi/metre)

Valpar 3/16 OD x .117″ MDP Tube = 5.8 psi/foot (19 psi/metre)

and you also must consider any height difference between keg and tap. The resistance from height is .5 psi/foot (1.64 psi/meter)

Typically the 3/8 run length and the height are known variables, therefore you will have the resistance they provide….then you make up the difference with the 3/16 (choker) line at the tap.

Hope that makes sense.

Cheers,

jeff

Sorry, very delayed in noticing the comment – this old blog is a bit neglected.

Yes, everything you say makes sense. Top-pressure is purely about carbonation as far as I’m concerned.

And it (plus temperature) is one variable along with line resistance, lift, and flow control in getting beer coming out of a tap right.

If your top-pressure for correct carbonation is good enough to dispense the beer, great! – if not then flojets or mixed gas are your options.

I take all of this into account when installing a draught system of course.

Life is so much simpler with coldstore based direct draw systems of course… 12C cellars, flash chillers, long python runs, shitting python cooling… it’s no wonder dispense in pubs for keg is such a nightmare really.

Comments are closed.